Table of Contents

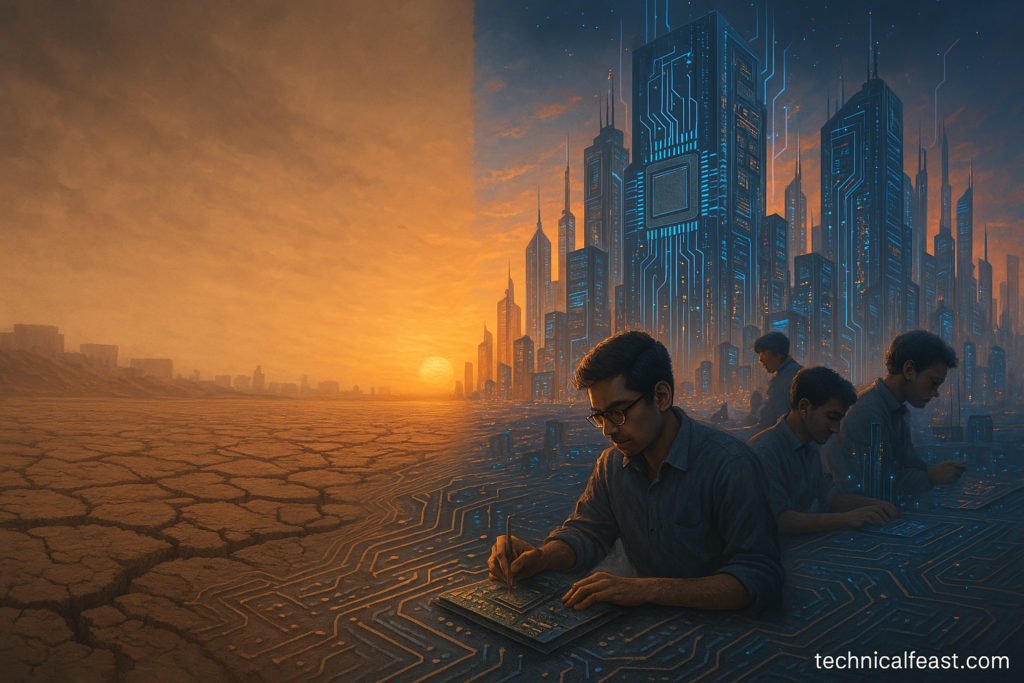

From Silicon Deserts to Silicon Dreams

Back in 2020, when I first started studying global tech supply chains, India’s absence in the semiconductor race always stood out. We had the talent, we had the market, but we didn’t have the fabs — those massive chip manufacturing units that power everything from your phone to satellites. Fast forward to 2023–24, and suddenly, headlines screamed about the India US semiconductor deal — a partnership that might just change the game for both countries.

This deal isn’t just about chips; it’s about sovereignty, economy, and strategic control in the post-pandemic digital age. With China dominating manufacturing and the US increasingly cautious about overdependence, India became a natural ally. And for India, this was a golden ticket to finally step into the high-value semiconductor ecosystem.

But is it really a game-changer, or just another diplomatic headline? Let’s break it down.

What Is the India US Semiconductor Deal?

At its core, the India US semiconductor deal is a bilateral agreement signed in 2023 between the Indian and US governments to collaborate on semiconductor manufacturing, research, design, and supply chain resilience.

Key elements include:

Setting up of joint semiconductor research and innovation hubs.

Facilitation of US tech companies like Micron Technology and Applied Materials in setting up units in India.

Workforce development and upskilling programs to train Indian engineers for the semiconductor sector.

Sharing of “trusted chip” technology to reduce dependence on Chinese tech.

The deal is aligned with broader frameworks like the US’s CHIPS and Science Act and India’s Semiconductor Mission. It’s not just a handshake—it’s a deep integration of supply chains and talent pools.

Why Is This Deal So Important?

To understand why the India US semiconductor deal matters, we have to look at the chip shortage crisis that hit global industries post-COVID. Car plants stalled, phone launches got delayed, and even defense tech struggled — all because of chip bottlenecks.

The US realized it couldn’t afford to rely solely on Taiwan or China for semiconductors. Meanwhile, India saw a $500+ billion global semiconductor market and knew it had the engineers and demand, but lacked infrastructure and capital.

This deal is like a bridge — one country has the ecosystem, the other has the market and manpower. Together, they can reduce global dependency on East Asia and build a more balanced tech supply chain.

Ground Impact: Micron’s Gujarat Facility and Local Benefits

One of the earliest outcomes of the India US semiconductor deal was the announcement of a $2.75 billion investment by Micron to set up an ATMP (Assembly, Testing, Marking, and Packaging) plant in Gujarat, India.

Out of this:

50% funding came from the Indian government.

20% support from the Gujarat state government.

The rest was Micron’s own investment.

This wasn’t just a symbolic move. The Gujarat plant is expected to create 5,000 direct jobs and over 15,000 indirect jobs, especially in the skilled and semi-skilled categories. It’s also being seen as a blueprint for future investments — a real-world result of the India US semiconductor deal and not just paper diplomacy.

I remember visiting Gujarat for a tech conference in 2023 — the mood was electric. For once, people weren’t talking about call centers or IT parks. They were talking about chip packaging units, supply chain logistics, and photolithography equipment. That shift in conversation felt like witnessing history.

Strategic Angle: Countering China and Strengthening QUAD

It would be naive to assume that the India US semiconductor deal is purely economic. There’s a strong strategic undertone, especially with rising US-China tensions and China’s aggressive tech push under “Made in China 2025.”

Semiconductors are now a national security asset. Whoever controls the chip supply chain controls digital infrastructure, AI capabilities, defense tech, and financial systems. That’s why the US is pushing allies like Japan, South Korea, and now India to be part of an alternative chip network.

India’s entry into this network:

Balances China’s influence in Asia.

Strengthens the QUAD alliance (India, US, Japan, Australia).

Aligns with the US’s “friendshoring” policy—moving supply chains to allied countries.

For India, this is also a long-term geopolitical win. It gives us a seat at the global tech leadership table, not just as a consumer, but as a producer.

Talent and Education: India’s Hidden Superpower

You can build factories, import machines, and draft policies. But without people to run it — especially in something as specialized as chip design and fabrication — it’s all wasted.

Here’s where India’s biggest weapon kicks in: engineers.

Under the India US semiconductor deal, there’s a big push to train 60,000+ engineers in chip design, VLSI (Very Large Scale Integration), fab operations, and related areas. Institutions like IIT Madras, IISc Bangalore, and even newer private universities have launched semiconductor-specific programs in partnership with US universities.

I spoke to a professor at IIT Bombay who told me: “This deal is the spark. We’ve had the talent, but not the fire. Now, students want to get into chip design instead of just software dev.”

That shift — from IT to deep tech — could redefine India’s education and employment landscape over the next 5–10 years.

Challenges Ahead: It’s Not a Plug-and-Play Game

Let’s be real: just signing a deal doesn’t magically create a semiconductor empire.

India still faces major hurdles like:

Infrastructure gaps: Water, power, clean rooms, etc.

Bureaucratic delays: Permits and clearances can kill momentum.

Supply chain gaps: We still rely on imports for advanced equipment.

High investment thresholds: Setting up a fab costs $10–15 billion.

Even US companies, despite their interest, are treading cautiously. The India US semiconductor deal is a great start, but implementation will make or break its success.

From a personal lens, I think India needs to treat this like how we did ISRO or UPI — long-term, state-backed, and independent of political cycles. The tech world won’t wait 20 years for us to catch up.

Policy Frameworks Behind the India US Semiconductor Deal

The foundation of the India US semiconductor deal isn’t just corporate interest — it’s backed by robust policy initiatives from both governments.

From the Indian Side:

India launched the Semicon India Programme in 2021 with a $10 billion incentive plan to attract semiconductor and display manufacturing. This includes:

50% capital support for setting up fabs.

30% subsidy for ATMP units.

Design-linked incentives (DLI) for startups in chip design.

As part of the India US semiconductor deal, these incentives were fine-tuned to attract US players by easing regulatory barriers, fast-tracking clearances, and aligning standards with US norms.

From the US Side:

The CHIPS and Science Act, passed in 2022, provides $52 billion in subsidies to revive domestic chip manufacturing in the US and encourage “friendly shore” expansion. The Act includes funding for:

R&D partnerships.

Talent exchange programs.

International collaborations with allies like India.

Together, these frameworks have given a structured base to the India US semiconductor deal. This isn’t a one-off handshake — it’s a multi-year roadmap built on policy, incentives, and mutual tech ambitions.

Impact on Indian Startups and Private Sector

While big headlines talk about Micron or Applied Materials, the deeper story is happening in India’s deep-tech startup ecosystem.

Startups like Sibros, Saankhya Labs, and Invecas are now in conversations for partnerships, funding, or tech transfers under the India US semiconductor deal. These startups, often working on chip design, edge computing, or 5G infrastructure, now have direct access to global supply chains.

Indian VCs are also shifting focus. Traditionally obsessed with fintech and edtech, we’re now seeing increased funding interest in fabless semiconductor startups and companies building tools for EDA (Electronic Design Automation).

Even conglomerates like Tata and Vedanta are jumping in, aiming to build India’s first integrated fabs. And yes, it’s risky — but the India US semiconductor deal gives them confidence that they won’t be alone in this fight.

As someone who’s worked with Indian startups, this is the most optimistic I’ve seen the ecosystem since the 2016 UPI wave.

Case Study Comparison: Taiwan, South Korea, and Vietnam

To understand how big the India US semiconductor deal could be, we must look at countries that succeeded in this space.

Taiwan:

Home to TSMC, the world’s largest chipmaker.

Government support began in the 1980s.

Invested early in R&D, human capital, and export incentives.

Today, Taiwan holds more than 60% of global foundry market share.

South Korea:

Backed giants like Samsung and SK Hynix with tech-focused tax breaks.

Invested heavily in chip innovation and protected domestic champions.

Currently ranks #2 in global semiconductor manufacturing.

Vietnam:

Positioned itself as a low-cost, geo-strategic alternative to China.

Focused on assembly, testing, and packaging rather than fabs.

Became a hub for multinational players like Intel and Samsung.

India is uniquely positioned to blend elements from all three models:

Like Taiwan, we have the R&D brains.

Like Korea, we can build public-private alliances.

Like Vietnam, we can provide geo-political leverage to Western companies.

The India US semiconductor deal takes cues from these success stories — but with an Indian flavor: scale, talent, and ambition.

How the Deal Is Reshaping India’s Global Image

For decades, India was seen as the IT back office of the world — doing service jobs, BPO, and coding for Western firms.

Now, for the first time, we’re entering the core manufacturing race for a product that powers everything from iPhones to fighter jets.

This shift has changed India’s global image:

From outsourcing hub to innovation partner.

From cheap labor market to strategic tech player.

From consumer of tech to producer of future technologies.

Diplomats, CEOs, and VCs I’ve spoken to in the past year are all saying one thing: “India’s no longer just the next billion users — it might be the next billion-dollar chip ecosystem.”

And the India US semiconductor deal is a key driver of this perception shift.

Long-Term Vision: What This Deal Means by 2030Let’s fast forward to 2030.

If the India US semiconductor deal stays on track, here’s what we can realistically expect:

1. At least 3-4 major ATMP plants operational in India.

2. One functional fabrication plant (fab)—most likely with Vedanta, Tata, or a US JV.

3. Over 100,000 trained chip professionals, from VLSI designers to packaging engineers.

4. Indian-designed chips powering IoT and automotive systems in global markets.

5. A ₹2 lakh crore Indian semiconductor economy, feeding both export and domestic consumption.

India’s digital economy is projected to be worth $1 trillion by 2030, and chips will be the invisible engine behind it. Whether it’s smart cities, EVs, 5G, or defense — no sector can grow without semiconductors.

This is why the India US semiconductor deal is not just policy — it’s infrastructure for India’s future.

Personal Take: Where We’re Winning, and Where We Still Lag

I’ve worked in the Indian tech space for nearly a decade. I’ve seen policy drafts go nowhere. I’ve seen MoUs signed and forgotten. But this time, something feels different.

The India US semiconductor deal has:

Actual investments.

Actual job creation.

Actual tech transfer.

However, our execution speed still lags. We can’t afford to move at bureaucratic pace in a race that updates every nanometer.

We also need to secure our own IP (Intellectual Property) — not just build chips for others, but design chips by Indians, for India, and for the world.

Still, I’m hopeful. This deal has lit a fire — and if we keep fanning it with good policy, private partnerships, and public momentum — we might finally have our Silicon Bharat moment.

The Chip War Has a New Player

The India US semiconductor deal is not just about silicon — it’s about sovereignty, global positioning, and long-term technological independence.

For India, it’s a golden opportunity:

To finally enter the high-tech manufacturing race.

To upskill its youth into deep-tech jobs.

To build an entire ecosystem from design to delivery.

For the US, it’s a strategic hedge:

To diversify supply chains beyond Taiwan and China.

To collaborate with a trusted democratic partner.

To scale its chip dominance with global manpower and local reach.

But let’s not sugarcoat it. It’s a tough road. Chipmaking is not quick money. It’s capital-intensive, time-consuming, and highly competitive. The key will lie in execution — turning signed papers into actual production lines, engineers, and IPs.

As someone who has seen India’s rise in digital payments, telecom, and even space, I truly believe — if we don’t waste this moment, we can be more than the world’s back office. We can be the world’s chipmaker.

And when that happens, we won’t just be a market for smartphones.

We’ll be a nation powering them.

FAQs About the India US Semiconductor Deal

Q1: What is the India US semiconductor deal?

It’s a bilateral agreement between India and the US to collaborate on semiconductor manufacturing, design, and supply chain resilience, signed in 2023 under larger global tech cooperation efforts.

Q2: What companies are involved in the deal?

Major players include Micron Technology, Applied Materials, and Lam Research. Indian giants like Tata, Vedanta, and Reliance have also shown interest.

Q3: How much is being invested?

Micron alone is investing $825 million in Gujarat, with total project cost reaching $2.75 billion with government support.

Q4: Will this deal create jobs in India?

Yes. Thousands of direct and indirect jobs will be created across engineering, design, operations, and support roles.

Q5: Can India really become a semiconductor hub?

Yes — but it will take 5–10 years of sustained investment, policy support, and skill development. The deal is a critical first step.Q6: How is the US benefiting from this deal?The US gains supply chain diversification, geopolitical leverage, and access to India’s engineering talent pool.

Leave a Reply